I recently had the absolutely incredible opportunity to visit the Holbein Paint manufacturing facility just outside of Osaka, Japan. This is one of two facilities Holbein operates in Japan and is where all of their water based paints (watercolours, acrylics and gouache) are manufactured, with their second factory dealing with their oil based products.

Holbein Art Materials is a fine art product manufacturer and brand founded in 1900. Focusing on providing incredible quality fine art materials over anything else, Holbein believe their products are on par with the best in the world, especially their watercolour range (which we stock in full!) A testament to this is Holbein currently employ 7 full time chemists to oversee every new colour and to make sure every variation is mixed to perfection.

Diving straight in I was guided through the building by Tets and his assistant, Juri. Both of whom were so incredibly welcoming and kind to me as soon as I met them. Tets and I enjoyed conversations on the bus ride to the factory about the fine art materials retail industry and the complex relationships between suppliers, distributors and retailers, especially within Australia.

Having worked for Holbein for over 20 years, Tets was a wealth of knowledge i enjoyed listening to him talk about the ever changing and evolving arts industry within Japan. He shared many funny anecdotal stories, like how many Japanese people have no idea that Holbein is actually a Japanese brand and all their products are made in Japan!

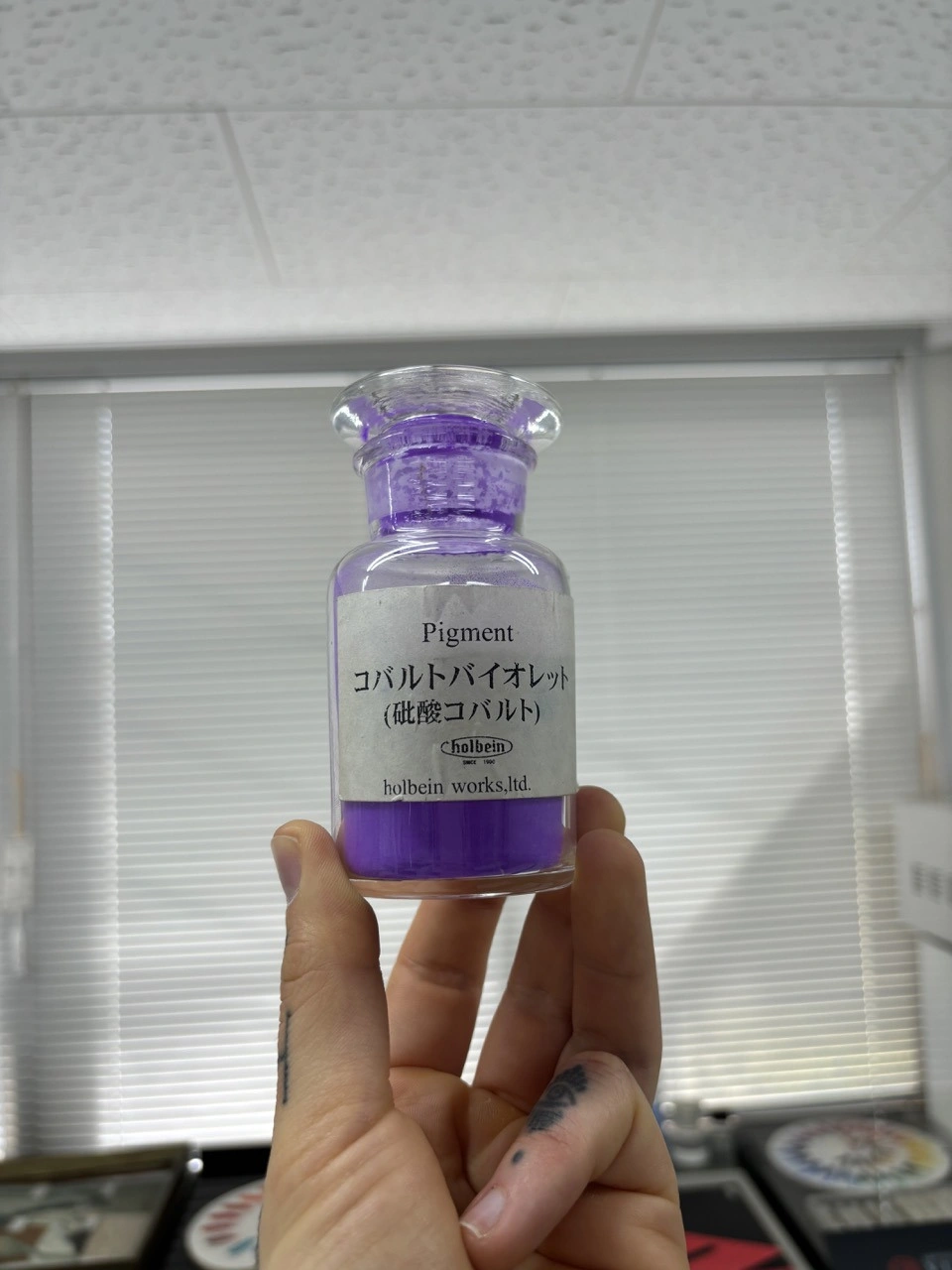

We started the tour with the fundamentals of how their paints were made, i was shown a simplified version of how they create a certain paint and then how they test that paint against the master sample.

Each and every batch of paint that is made in every single colour is rigorously tested and then compared to the master sample at each stage of the paint making process. A tiny variation in colour at the start of the paint making sequence (something you or I would not be able to even tell the difference between) down the line can make a huge difference in the final colour of the paint.

From here we entered a part of the factory floor, I witnessed two workers adding various compounds together (secret recipe!!) to create some of their acrylic mediums and their Quinacridone Magenta watercolour paint being hand mixed, the stage before the paints are put through the 3 stages of milling.

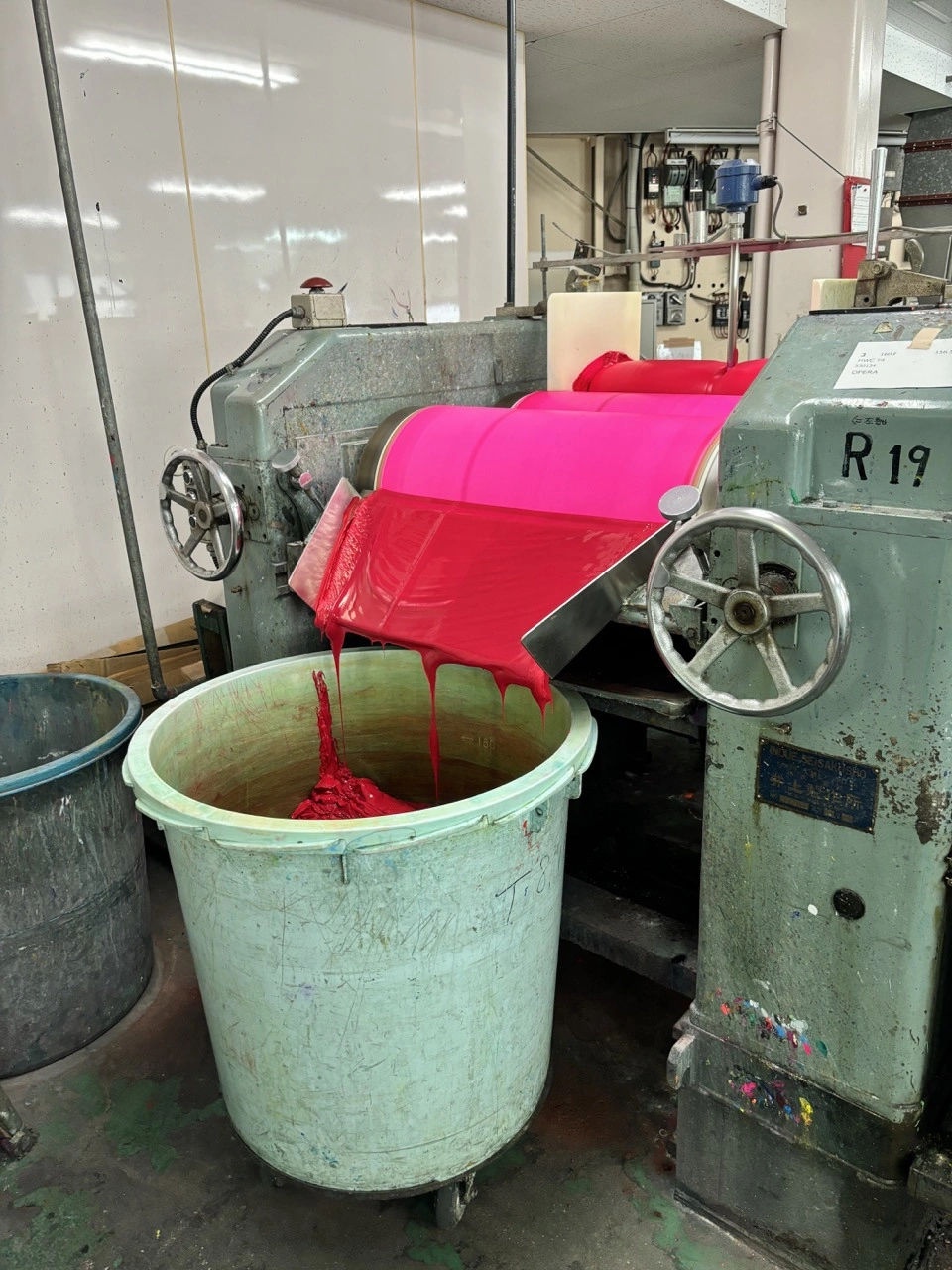

From here I was taken to where there are 3 different rollers operating at once.

The paint is put through these rolling machines up to 10 times for certain varieties of the Holbein paints depending on the pigment used. I was very lucky as the day I walked through was called a "pretty" day! I saw colours like cadmium green and opera pink going through the rollers, a lot more exciting than a day of browns!

The rolling process (or milling process) is when the paint is put into a machine where 3 rollers (Normally either ceramic or stainless steel) spin in different directions as the paint is pushed in and out between them. This process is all about dispersion and separating the particles within the pigment. The higher the rate of dispersion within paint leads to ultimately a better overall paint for a number of reasons, such as:

- A smoother paint (duh!) the more a paint is milled and particles are separated will remove/minimize any sort of clumps because no one likes clumpy paint, do they?

- As more particles are separated from each other, the particles themselves have a greater surface area for binders to hold onto, meaning the paint is less likely to seperate at any stage

- A paint that has been milled correctly and adequately will last longer. Properly dispersed pigments are stronger being more resistant to cracking, fading and the atmospheres elements over time

- And finally properly milled pigment allows for an even and consistent dispersion throughout the paint, creating stronger hiding power.

Different pigments sometimes require different rollers, steel rollers which are harder than ceramic are used when a pigment is especially hard, these pigments are normally also put through the entire process of milling sometimes double the amount of other pigments.

I asked the workers which pigment was the hardest and it was the most definitive answer i had ever gotten, Cerulean Blue. Cerulean Blue needs to be put through the milling process more than any other pigment (this is part of the reason Cerulean is generally a higher series of paint).

While the softer pigments are normally your earthy tones (Umbers etc)

All Holbein paints undergo one final test, Lightfastness.

A paints lightfast rating or measurement is how long the paint will hold up against light. A higher quality paint will last longer exposed to light and will take much longer to fade vs a lesser quality or student grade paint.

To test this the paints are put into a machine and blasted with an incredibly intense artificial light to mimic exposure to UV rays. The paint will the face the equivalent amount of up to 100 years of sunlight or UV rays in the space of a bit over a week. I'd never actually seen one of these machines before so I was utterly fascinated, it was huge as well!

From here I was taken the where the paint is tubed and capped and them moved to where the tubes are out into sets and boxed. This boxing of all Holbein sets is still done by hand! Holbein believe any machine will create dents or imperfections in packaging and this is a big no no in Japan. As Tets said to me "The Japanese people would not tolerate this, there cannot be any fault in the tubes or packaging!" A true testament to the high quality standards in Japan.

Finally I was taken outside where coloured water (in this case bright purple) was being pumped into a small pool like enclosure. This was the remnants of a paint run. Holbein is committed to the environment and this was the start of the process of separating every single piece of pigment from remaining water used in the facility. Only when he water ran clear after going through 4 different stages was it then let off into a nearby river.

It may be hard to see in the below photo, but you can see purple water being pumped into the pool.

It was an absolute honour to be given a tour of this wonderful facility, Holbein were so incredibly accommodating. The Launceston Art Centre looks forward to building our relationship with Holbein and to continue provide the Launceston community with their incredible range of products.

Holbein paints are world class in quality, they believe it and genuinely, we do too.